High-Performance Coating for Marine and Industrial Applications

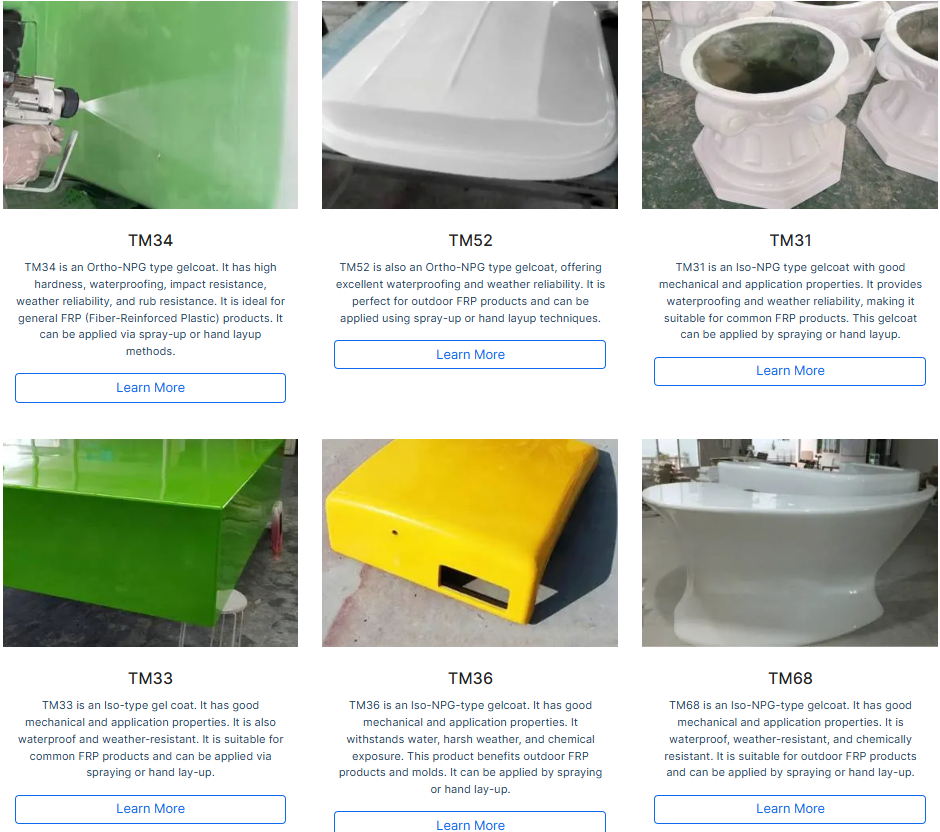

Gelcoat Resin is a specialized material used to create smooth, durable, and glossy surfaces on fiberglass-reinforced products. Commonly applied in the marine, automotive, and construction industries, this protective layer enhances both the visual appeal and structural integrity of various products. It serves as a barrier against moisture, UV rays, and environmental damage, ensuring longevity and resistance to wear and tear. Manufacturers prefer gelcoat resin for its exceptional adhesion properties, allowing it to bond seamlessly with fiberglass structures while maintaining a flawless finish.

Advanced Formulation for Superior Weather Resistance

One of the most significant advantages of gelcoat resin is its ability to withstand extreme weather conditions. Engineered with high-performance polymers, this material offers outstanding resistance to fading, chalking, and blistering caused by prolonged exposure to sunlight and water. The unique composition of gelcoat resin includes additives that enhance its flexibility and impact resistance, preventing cracks and surface degradation over time. Whether used in boat hulls, wind turbine blades, or recreational vehicles, this resin ensures a lasting and vibrant appearance without frequent maintenance.

Seamless Application for Long-Lasting Protection

Applying gelcoat resin requires precision and expertise to achieve a flawless and uniform finish. Professionals use spray or brush techniques to evenly distribute the resin over fiberglass surfaces, allowing it to cure into a hard, protective shell. Proper surface preparation, including cleaning and sanding, is essential for optimal adhesion and durability. With the right application methods and high-quality formulations, gelcoat resin provides superior protection, enhancing both the performance and aesthetic appeal of a wide range of composite products.